Are you struggling with winding and twisting in your lifting operations? It’s a common frustration that can lead to safety issues and project delays.

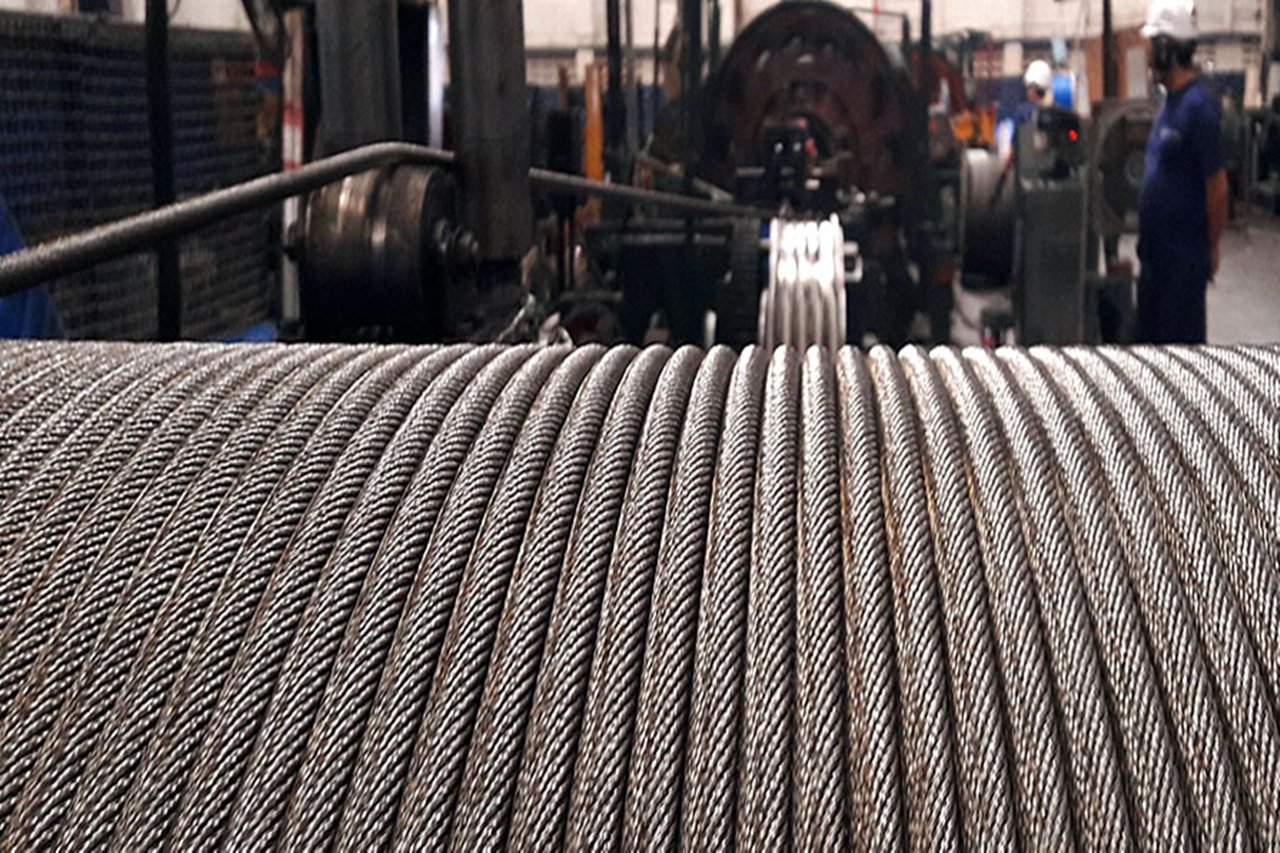

A non-rotating wire rope is a specialized type of wire rope designed to minimize or eliminate torsional forces, allowing it to maintain its shape and stability under load without twisting.

Let me tell you, I’ve seen firsthand how the wrong rope can turn a smooth operation into a tangled mess. But finding the right solution can feel like searching for a needle in a haystack.

Why is Non-Rotating Wire Rope Crucial for Lifting Applications?

Understanding the benefits of non-rotating wire rope can significantly improve your lifting efficiency and safety margins.

This type of rope is essential because it resists the tendency to spin, providing stable and predictable load control during vertical lifting.

Understanding Torsional Forces in Wire Ropes

Torsional forces are generated when a load is lifted, causing the wire rope to unwind or spin. This is especially problematic in single-part lifting applications where there’s no counteracting force.

Benefits of Using Non-Rotating Wire Rope

- Reduced Twist: The rope’s construction minimizes spinning, leading to more stable lifts.

- Improved Control: Operators have better command over the load, enhancing safety.

- Increased Lifespan: Less torsional stress means the rope is less likely to deform and wear out prematurely.

- Enhanced Safety: By preventing uncontrolled spinning, the risk of accidents is significantly lowered.

Applications Where Non-Rotating Ropes Excel

| Industry | Application | Key Benefits |

|---|---|---|

| Construction | Tower cranes, mobile cranes | Stable load handling, reduced operator fatigue |

| Mining | Hoisting systems, draglines | Durability, consistent performance in harsh conditions |

| Marine | Hoisting, towing | Resistance to saltwater corrosion and twisting |

| Elevator | Hoisting systems | Smooth and stable vertical movement |

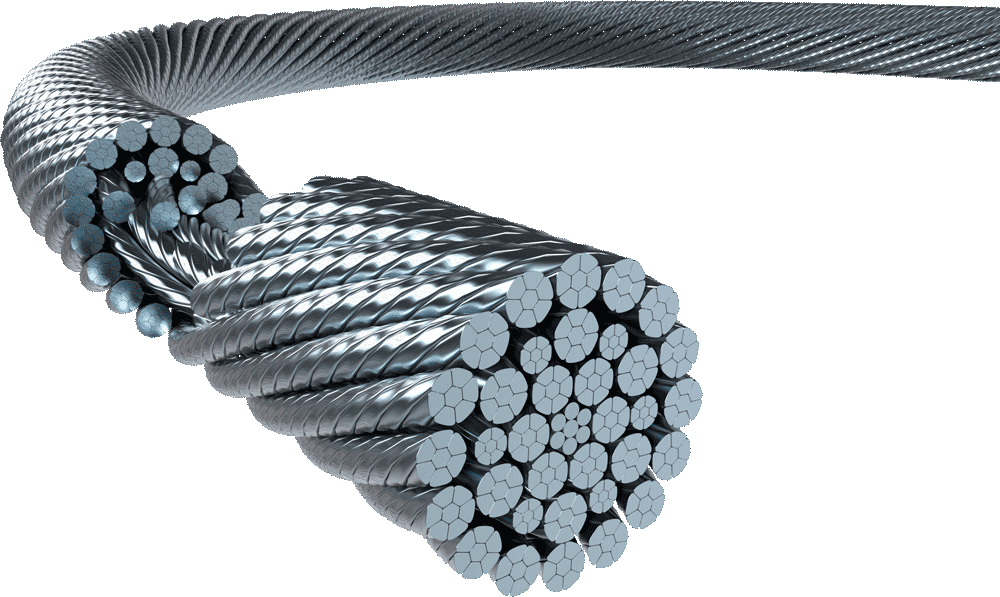

How is Non-Rotating Wire Rope Constructed?

The unique properties of non-rotating wire rope come from its specialized construction methods.

The construction involves layering wire strands in opposite directions to neutralize torque.

I remember a time when a simple lift turned into a complicated problem because of rope twist. It was a real eye-opener, and that’s when I started looking into better solutions.

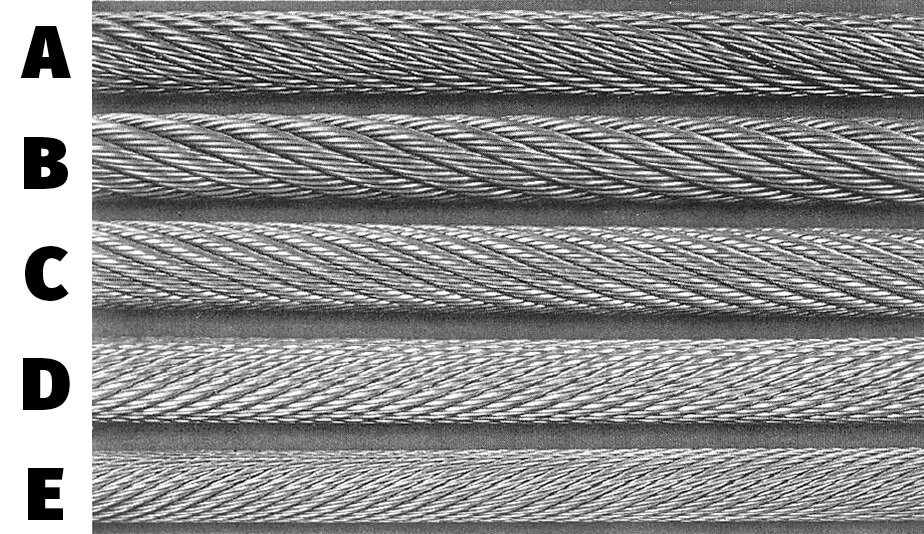

The Science Behind Torque Neutralization

Non-rotating wire ropes achieve their stability through specific lay constructions. Typically, they feature an inner set of strands laid in one direction and an outer layer of strands laid in the opposite direction. This opposing lay counteracts the torque generated as the rope is loaded.

Common Types of Non-Rotating Wire Rope

- 18×7 Non-Rotating Wire Rope: This is a very common type, often referred to as “non-spin” or “anti-twist” rope. It uses 18 strands, each composed of 7 wires, laid around a core. The outer strands are laid in the opposite direction to the inner strands.

- 35×7 Non-Rotating Wire Rope: A heavier-duty option, this rope has a higher number of strands, offering even greater resistance to rotation.

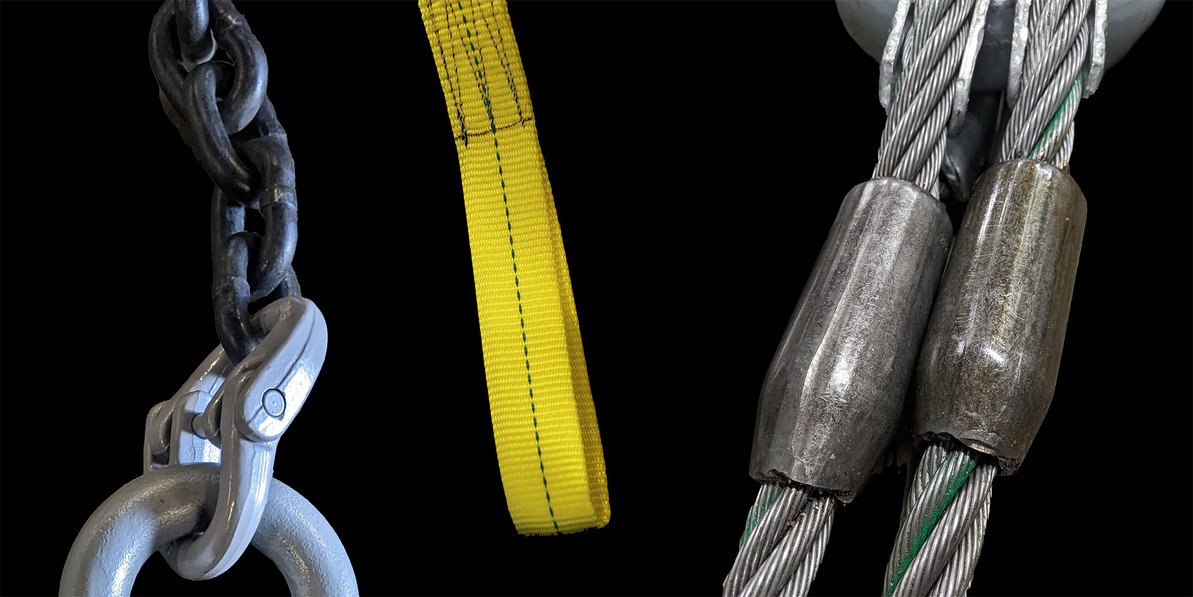

Factors to Consider When Choosing Non-Rotating Rope

- Load Capacity: Ensure the rope’s breaking strength meets your lifting requirements.

- Working Load Limit (WLL): Always adhere to the WLL for safe operation.

- Environment: Consider factors like corrosion resistance and temperature.

- End Terminations: The type of terminations (loops, sockets) needed will affect the rope’s overall performance.

What are the Advantages Compared to Standard Wire Rope?

Differentiating between standard and non-rotating wire ropes is key to selecting the most suitable option for your task.

Standard wire ropes tend to twist under load, compromising stability and increasing wear.

It’s not just about the twist; it’s about how that twist affects the entire lifting process and, more importantly, the safety of everyone involved.

Comparison of Performance Characteristics

| Feature | Standard Wire Rope | Non-Rotating Wire Rope |

|---|---|---|

| Rotational Tendency | High | Very Low |

| Stability Under Load | Moderate | High |

| Operator Skill | Requires experience | Easier to handle |

| Lifespan | Can be shorter | Generally longer |

| Application Limit | Not ideal for single part lifts | Suitable for single part lifts |

When is Standard Wire Rope Still a Good Choice?

Standard wire ropes are often more economical and suitable for applications where rotational forces are less of a concern, such as in multi-part reeving systems where the torque is naturally counteracted.

Any lifting application that doesn’t involve a single part lifting the load directly can often use standard wire rope effectively.

Conclusion

Opting for non-rotating wire rope ensures safer, more stable, and efficient lifting operations.

I always recommend checking certifications like BV, CE, RMRS, DNV, and ABS based on your needs. We provide these to clients who require them.

Choosing the right rope is critical for operational success and safety.