Are you worried about your wire rope corroding? It’s a common concern for anyone relying on strong, durable lifting and pulling solutions. Discover the truth about galvanized wire rope and its resistance to rust.

Galvanized wire rope is designed to resist rust due to its protective zinc coating, offering significantly enhanced durability in corrosive environments compared to bare steel.

Let’s explore how that protective layer works and what you can expect when you choose galvanized for your critical applications.

What Makes Galvanized Wire Rope Resistant to Rust?

Understanding the science behind galvanization is key to appreciating its protective qualities. We dig into the zinc coating.

The zinc coating on galvanized wire rope acts as a sacrificial barrier, corroding preferentially to protect the underlying steel from rust.

This process is crucial for maintaining the structural integrity and lifespan of the rope, especially in harsh conditions.

The Galvanization Process: Zinc’s Protective Embrace

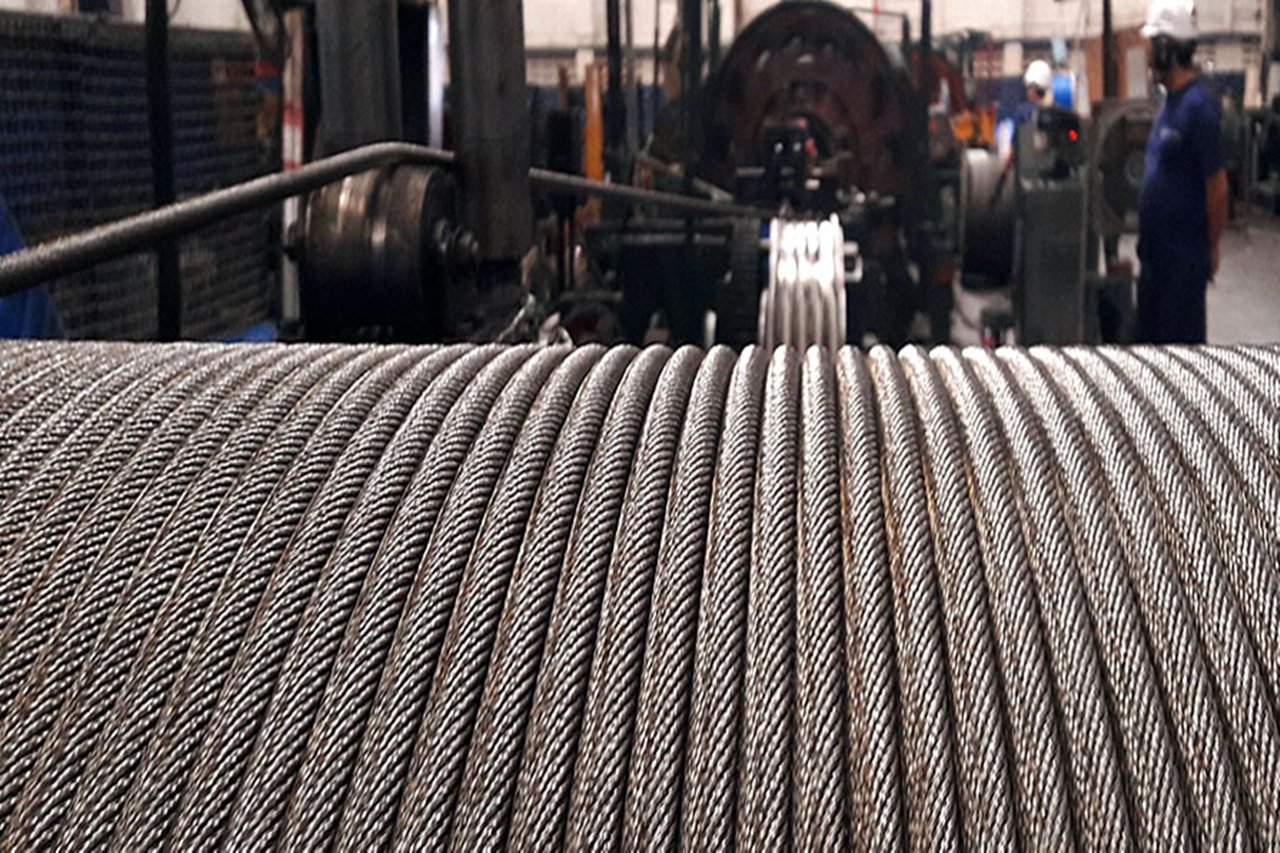

Galvanization involves coating steel wire with a layer of zinc. This is typically done through hot-dip galvanizing, where the wire is submerged in a bath of molten zinc. The zinc then alloys with the steel, forming a metallurgical bond.

This bond creates a robust, multi-layered coating that offers excellent protection. The zinc also has a unique property: it can electrochemically sacrifice itself to protect the steel. Even if the coating is scratched, the zinc nearby will corrode before the steel, preventing rust from spreading.

Understanding Sacrificial Protection

This phenomenon is known as galvanic protection. Zinc is more electrochemically active than iron (the main component of steel). When exposed to an electrolyte (like moisture or saltwater), the zinc will corrode first, acting as a “sacrificial anode.”

Here’s a simplified breakdown of how it works:

| Element | Electrochemical Property | Role in Protection |

|---|---|---|

| Zinc (Zn) | More Anodic | Sacrificial anode |

| Iron (Fe) | More Cathodic | Protected cathode |

As long as there is zinc present, it will preferentially oxidize, leaving the steel protected from rust.

What Happens if the Zinc Coating is Compromised?

While galvanized wire rope offers excellent protection, understanding what happens when the coating is damaged is important for maintenance.

If the zinc coating is severely damaged or worn away, the exposed steel can begin to rust, compromising the rope’s integrity and lifespan.

It’s essential to monitor the condition of your wire rope to ensure continued optimal performance and safety.

Signs of Coating Damage and Potential Rust

Regular inspection is vital. Look for:

- Chipping or flaking zinc: This indicates the coating is starting to break down.

- Discoloration: Patches of reddish-brown or black on the rope can be early signs of rust.

- Pitting or deep scratches: Significant mechanical damage can remove the zinc.

- White rust: This is zinc corrosion, which is less harmful than iron rust but still signifies zinc depletion.

If you notice any of these signs, it’s time to assess the extent of the damage.

Impact of Environmental Factors on Durability

The environment plays a significant role in how well galvanized wire rope performs:

- High Humidity and Moisture: Prolonged exposure can accelerate zinc corrosion, even if the base metal is protected.

- Saltwater/Marine Environments: These are particularly corrosive. While galvanization offers good protection, constant immersion can eventually wear down the zinc.

- Chemical Exposure: Certain industrial chemicals can degrade the zinc coating more rapidly.

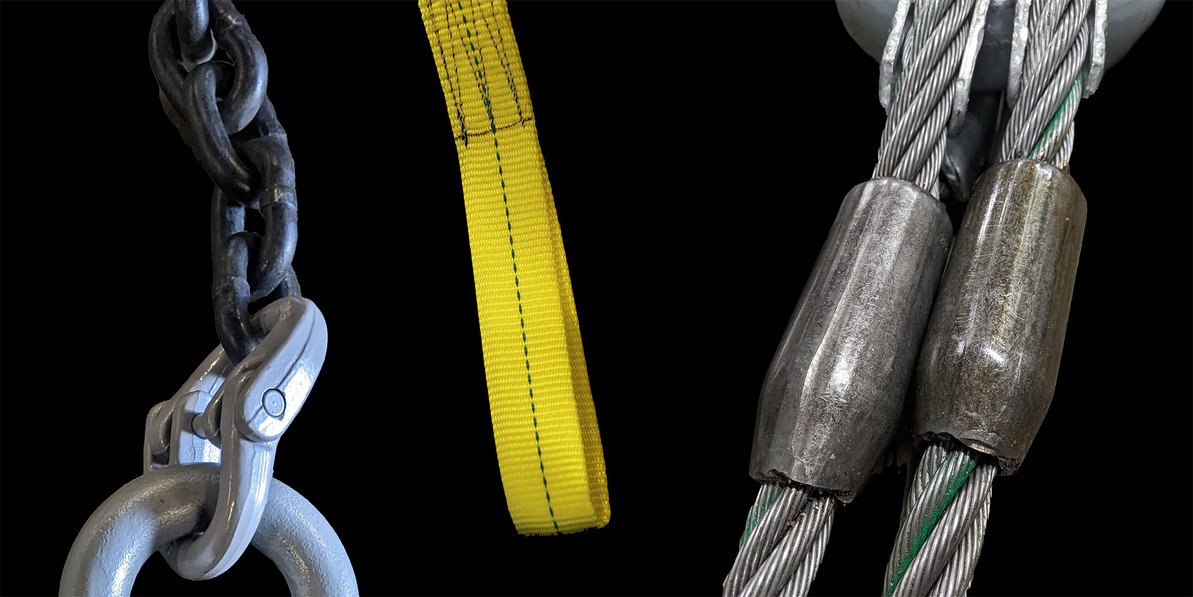

We offer specific types of galvanization, including plastic-impregnated and galvanized options, which provide even greater protection in challenging conditions.

How to Maximize the Lifespan of Your Galvanized Wire Rope

Proper care and handling ensure your galvanized wire rope lasts as long as possible. Focusing on quality and understanding the product is key.

To maximize the lifespan of your galvanized wire rope, proper storage, handling, and regular inspection are crucial to maintain the integrity of the protective zinc coating.

We provide high-quality wire ropes, including crane wire rope and elevator wire rope, manufactured to strict standards like EN12385-4, ensuring optimal performance.

Proper Storage and Handling Practices

- Storage: Store wire rope on reels in a cool, dry, well-ventilated area, away from direct sunlight and corrosive substances. Avoid coiling rope on the ground.

- Handling: Use appropriate lifting equipment to avoid kinking or crushing the rope. When unreeling, ensure the reel rotates smoothly to prevent damaging the wires.

The Importance of Regular Inspections

Consistent visual checks are non-negotiable:

- Filtration: Regularly clean the rope to remove dirt and debris that can trap moisture and accelerate corrosion.

- Lubrication: While galvanized rope has a built-in protective layer, specialized lubricants can further enhance its resistance to corrosion and reduce wear. We offer plastic-impregnated options for enhanced protection.

- Record Keeping: Maintain a log of inspections, noting any wear, damage, or signs of corrosion.

When to Replace Your Wire Rope

Replace your wire rope if:

- Significant corrosion or rust is visible.

- There are broken wires, especially in noticeable patterns.

- The rope has been kinked, crushed, or overloaded.

- The outer wires show excessive wear or distortion.

We offer a wide range of wire rope products, including mining wire rope and stainless steel wire rope, each designed for specific demanding applications. Our factory boasts 10 production lines, allowing us to meet diverse customer needs and provide certificates like BV, CE, RMRS, DNV, and ABS upon request.

Conclusion

Galvanized wire rope offers excellent rust resistance thanks to its protective zinc coating, but proper care ensures its longevity.