Wire rope is one of the most essential components in modern engineering, construction, mining, and marine operations. Its strength, flexibility, and versatility make it the backbone of lifting and rigging activities. However, choosing the right wire rope is not always straightforward. Different environments, load requirements, and operating conditions demand specific rope constructions and materials. Selecting the wrong rope can lead to premature wear, costly downtime, or even dangerous accidents.

This guide provides a comprehensive overview of the key factors to consider when selecting wire rope, ensuring safety, efficiency, and long service life.

1. Understanding the Application

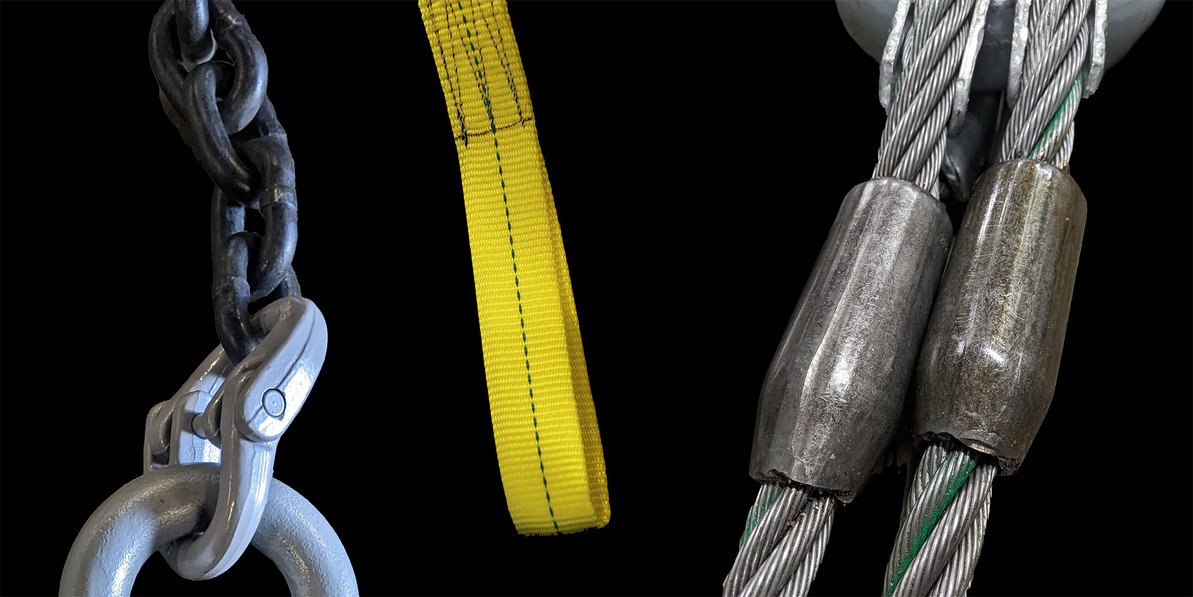

The first step is to define where and how the wire rope will be used. Wire ropes are designed for different applications, and performance requirements vary widely:

- Cranes & Hoists: These require rotation-resistant or non-rotating ropes to prevent load twisting.

- Construction & Infrastructure: General-purpose ropes are often used, but durability against wear is crucial.

- Marine & Offshore: Galvanized or stainless steel ropes are essential to withstand saltwater corrosion.

- Mining & Quarrying: Heavy-duty ropes with high abrasion resistance and strength are required for hoisting and draglines.

- Elevators & Lifts: Smooth-running ropes with precise construction for safety and comfort.

- Winches & Logging: Ropes that combine strength with flexibility for frequent winding and unwinding.

By clearly defining the environment and the type of load movement (lifting, pulling, suspending, anchoring), you can narrow down the rope options.

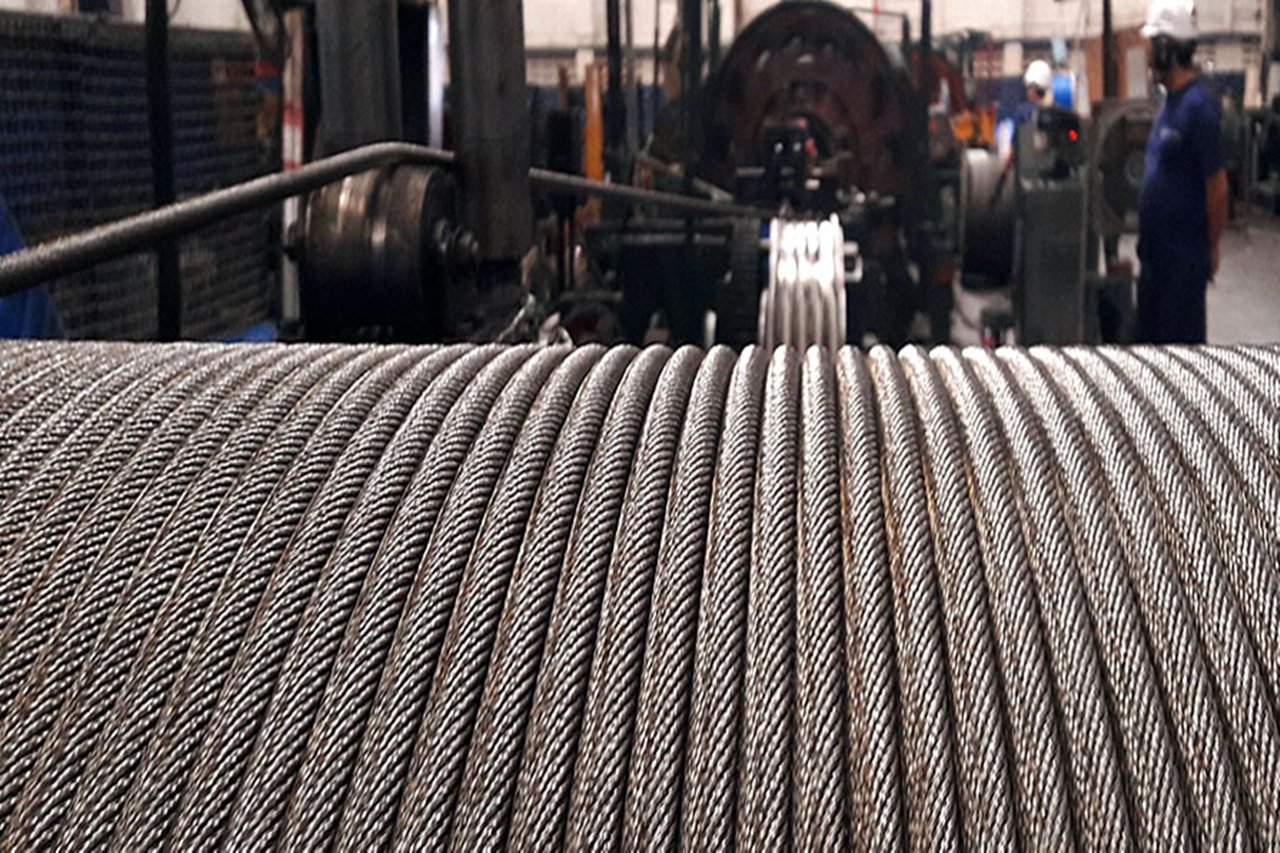

2. Rope Construction

Wire ropes consist of strands twisted around a central core, and their construction determines both performance and durability.

- 6-Strand Ropes:

- The most common construction.

- Offer good flexibility and balance of strength.

- Ideal for general lifting and rigging.

- 8-Strand Ropes:

- Provide better wear resistance and fatigue life.

- Common in heavy-duty cranes, offshore operations, and ship cranes.

- Non-Rotating / Rotation-Resistant Ropes:

- Designed with opposing strand layers to minimize spin under load.

- Essential for tower cranes, mobile cranes, and high lifts.

- Compacted & Plastic-Coated Ropes:

- Compacted strands increase metallic cross-section, improving breaking load and abrasion resistance.

- Plastic coating between the core and strands adds corrosion protection and reduces internal wear.

Each construction offers a different balance of strength, flexibility, fatigue resistance, and rotation control.

3. Core Types

The core supports the rope’s strands and contributes to its performance:

- Fiber Core (FC):

- Made of natural or synthetic fibers.

- More flexible and lightweight.

- Not as strong or crush-resistant; less suitable for heavy-duty use.

- Independent Wire Rope Core (IWRC):

- A small wire rope used as the core.

- Increases strength by 7–10% compared to FC.

- Offers superior crush resistance, stability, and durability.

- Widely used in cranes, winches, and demanding lifting applications.

In most modern heavy-duty applications, IWRC is preferred due to its higher strength and longer service life.

4. Material and Surface Finish

Wire ropes are manufactured from different steels and finishes, affecting corrosion resistance and durability:

- Bright (Ungalvanized) Steel:

- Standard finish, widely used in indoor or dry environments.

- Less protection against corrosion.

- Galvanized Steel:

- Provides a zinc coating to resist rust.

- Ideal for outdoor or moderately corrosive environments.

- Cost-effective alternative to stainless steel.

- Stainless Steel:

- High resistance to corrosion, chemicals, and saltwater.

- Common in marine, offshore, and architectural applications.

- More expensive but offers long-term durability in harsh environments.

5. Strength and Safety Factor

The breaking load or minimum breaking load (MBL) defines the maximum force a rope can withstand. However, for safety, wire ropes should never be loaded to their breaking point.

- Working Load Limit (WLL) is calculated by dividing the MBL by a safety factor (commonly 5:1 to 7:1 for lifting applications).

- For example: A rope with MBL of 50 tons, using a 5:1 factor, has a WLL of 10 tons.

Always ensure that the rope selected meets or exceeds the load requirements of the application with the appropriate safety margin.

6. Diameter and Equipment Compatibility

Choosing the correct rope diameter is critical for smooth operation and long service life:

- The rope must match the size of sheaves, drums, and fittings.

- Incorrect diameter can cause excessive wear, crushing, or rope failure.

- Follow the manufacturer’s specifications for rope-to-sheave diameter ratio (D/d ratio).

For example, a rope running over too small a sheave will experience higher stress and reduced lifespan.

7. Operating Environment

Environmental conditions strongly influence rope performance:

- High Temperatures: Require heat-resistant wires or special lubrication.

- Wet or Corrosive Environments: Use galvanized or stainless steel ropes.

- Heavy Abrasion: Compacted or plastic-coated ropes extend service life.

- Low Temperatures: Ropes must maintain flexibility and avoid brittleness.

Selecting the right surface finish and protective design is essential for maximizing rope durability in specific environments.

8. Maintenance and Inspection

Even the best wire rope will fail prematurely if not maintained properly. Key practices include:

- Regular Lubrication: Prevents corrosion and reduces internal friction.

- Inspection: Monitor for broken wires, kinks, corrosion, or diameter reduction.

- Timely Replacement: Follow discard criteria such as maximum broken wire count, reduction in diameter, or core failure.

A well-maintained rope not only lasts longer but also ensures safe operations.

9. Standards and Certification

Wire ropes are manufactured according to international standards such as:

- EN 12385 (Europe)

- ISO 2408 (Global)

- ASTM / ASME (USA)

- DIN Standards (Germany)

When purchasing, ensure that the rope meets relevant standards and, if required, third-party testing or certification. This guarantees quality, consistency, and safety compliance.

✅ Conclusion

Choosing the right wire rope requires careful evaluation of:

- Application and environment

- Rope construction and core type

- Material and surface finish

- Breaking load and safety factor

- Diameter and equipment compatibility

By considering these factors and adhering to safety standards, you can select a rope that delivers strength, durability, and reliability for your operations. A well-chosen wire rope not only improves efficiency but also safeguards workers and equipment.