Offshore cranes operate in one of the harshest environments for lifting equipment: salt spray, heavy cyclic loads, shock loading, and long service intervals. Choosing the right wire rope is critical for safety, uptime, and lifecycle cost. Below I give a practical, technically-focused guide you can use when specifying or buying wire rope for offshore crane applications.

1 — What you must prioritize

When selecting a rope for an offshore crane, rank these in order of importance for your application and operating profile:

- Fatigue resistance — cranes see millions of load cycles; fatigue life drives replacement intervals.

- Abrasion and corrosion resistance — saltwater and contact with deck fittings accelerate wear.

- Breaking strength / safety factor — must meet design load × required safety factor per rule/standard.

- Flexibility and bending fatigue — reeving over sheaves and drums requires appropriate construction.

- Spooling behaviour — good layer-winding reduces local bending and wear on drums.

- Inspection & maintenance friendliness — ease of visual/NDI inspection to detect core or internal wire breaks.

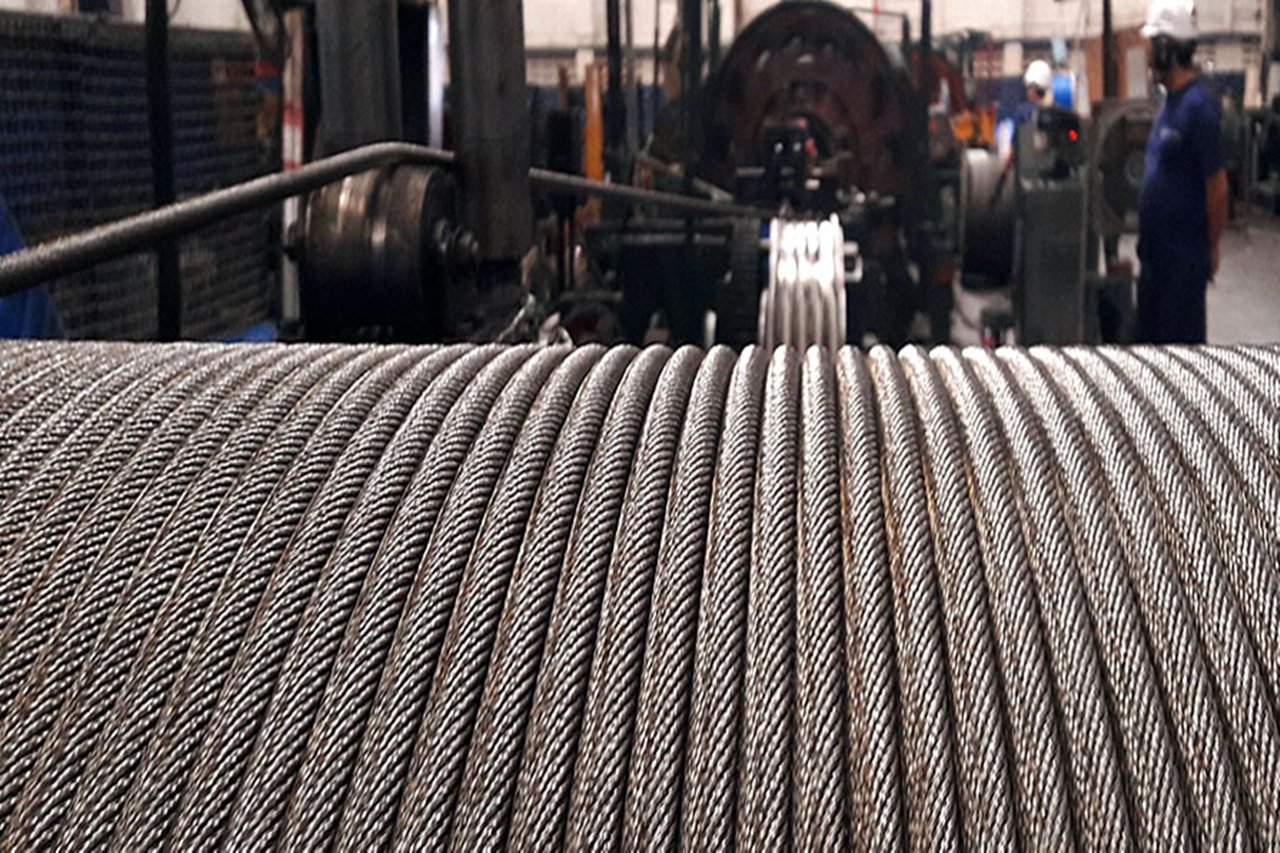

2 — Typical rope constructions used offshore

Not every construction is equal. Common offshore crane choices:

- 6×36 (Seale / Warrington / Filler) — a flexible construction with good fatigue and abrasion balance; often used for winch and secondary lines.

- 6×37 / 6×36WS (Warrington–Seale variants) — commonly chosen when a balance of flexibility and wear resistance is required.

- 8×K (e.g., 8×K26 / 8×K36) — offers excellent flexibility and better fatigue for applications with small sheave diameters.

- 35W (e.g., 35W×7, rotation-resistant) — used for hoist ropes where rotation control matters; high compactness, good fatigue.

- Rotation-resistant (RR) and non-rotating constructions — selected for tandem lifts or where load rotation must be minimized.

Useful shorthand examples you’ll see on spec sheets: 6×36WS-IWRC, 8×K26-EPIWRC, 35WXK7.

3 — Core choices: IWRC vs FC vs EPI

- IWRC (Independent Wire Rope Core) — steel core; higher strength, better resistance to crushing and heat, preferred for hoisting and heavy duty offshore ropes.

- FC (Fiber Core, e.g., polypropylene or natural fiber) — more flexible and lubricating but less crush-resistant and lower strength — rarely used for main crane hoists offshore.

- EPIWRC / Polyester impregnated cores — combine benefits of steel core with improved internal corrosion resistance and lubrication retention; commonly used in marine environments.

For offshore cranes I recommend IWRC or impregnated cores for hoisting and load-bearing lines.

4 — Material and coating

- Bright (uncoated) steel — cheaper but corrodes rapidly offshore; needs intensive lubrication and maintenance.

- Galvanized — zinc coating gives sacrificial protection and is common for mooring/towing; for repeated flexing (hoist) galvanized wires can wear/chafe faster internally.

- Plastic-coated (PVC/Polyethylene) — improves abrasion and corrosion resistance and spooling, commonly used for mooring and towing lines but increases diameter and can hide internal corrosion — inspect carefully.

- Stainless steel — excellent corrosion resistance but expensive and lower fatigue strength in many constructions; used in specialized cases.

- Lubrication & sealed/impregnated ropes — ropes with factory impregnation and sealing dramatically reduce internal corrosion and extend life offshore.

Recommendation: for primary hoist and load-bearing ropes, use galvanized or impregnated IWRC ropes (plus routine lubrication). For mooring/towing on deck, consider plastic-coated or heavily galvanized ropes.

5 — Fatigue, abrasion, and sheave/drum compatibility

- D/d ratio (sheave diameter / rope diameter): smaller sheave diameters increase bending stress and reduce fatigue life. Always check rope manufacturer recommendations and keep D/d as large as practicable. Typical target: D/d ≥ 20 for heavy cyclic hoist applications when possible.

- Drum groove design & spooling: matched grooves and proper flange geometry avoid cross-stacking and crushing. Layer-winding drums require careful groove profiling.

- Sheave material & maintenance: hardened sheaves and regular lubrication increase rope lifetime.

6 — Certification and standards

For offshore use, ensure ropes and suppliers comply with:

- Classification society rules (ABS, DNV, Lloyd’s, BV, RMRS etc.) for offshore cranes and lifting gear.

- ISO 3533 / EN 12385 family for wire rope manufacturing, testing, and inspection practices (check the specific part relevant to your construction).

- Supplier factory test records (breaking tests, elongation, lay length, torque if applicable) and traceable heat-treatment/chemistry data.

When requesting quotes, always ask for the manufacturer’s mill certificates, test reports, and classification approvals relevant to crane/hoist service.

7 — Inspection, lubrication, and replacement criteria

- Routine visual inspection: check for external broken wires, corrosion, diameter loss, bird-caging, and severe wear at contact points.

- Non-destructive testing (NDT): magnetic flux leakage or electromagnetic techniques can detect internal broken wires and core corrosion — valuable offshore where internal deterioration is common.

- Lubrication schedule: factory-impregnated ropes still need periodic re-lubrication, especially in saltwater spray environments. Use marine-grade rope lubricants that displace water and protect internal wires.

- Replacement criteria: follow classification society rules and manufacturer recommendations (e.g., number of broken wires per lay, diameter reduction percentage, visible core corrosion). Keep detailed logs of cycles and inspection findings.

8 — Practical specification checklist you can copy into RFQs

- Operating load / SWL and maximum dynamic peaks (kN or tons).

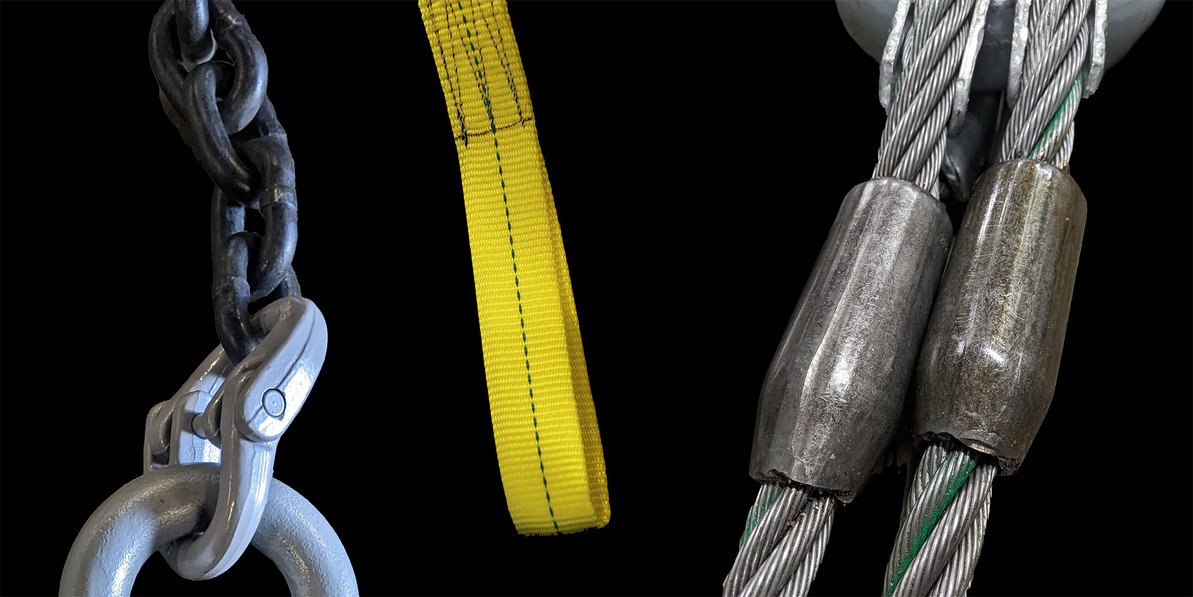

- Rope application: hoist / luff / pendant / reeving / towing / mooring.

- Rope diameter (mm) and nominal breaking force (kN) required plus safety factor.

- Construction (e.g., 6×36WS-IWRC, 8×K26-EPIWRC, 35W×7 non-rotating).

- Core: IWRC / EPIWRC / FC.

- Finish: Galvanized / Bright / Plastic coated (specify thickness) / Stainless grade.

- Lubrication: factory-impregnated + recommended re-lubrication schedule.

- Certification: specify class society approvals and EN/ISO standards required.

- D/d minimum for sheaves; drum groove profile or drum winding method.

- Proof testing requirements (percentage of MBL), breaking test sample retention, and mill test certificates.

9 — Example recommendations (typical)

- Main hoist (heavy cyclic, critical): 35W×7 or 6×36WS-IWRC, galvanized, factory-impregnated, proof tested to 90% MBL, class-approved.

- Luffing / pendant where bending is moderate: 6×36WS-IWRC, galvanized or EPIWRC.

- Towing/mid-deck mooring lines: Plastic-coated 8×K constructions or 6×36 galvanized, depending on abrasion needs.

- Non-rotating needs (special lifts): Rotation-resistant constructions designed for the specific crane geometry.

10 — Final practical tips

- Always match rope choice to actual duty cycle — high cycles demand different ropes than occasional heavy lifts.

- Buy from recognized rope mills with experience in marine/offshore products and request sample test reports.

- Consider lifecycle cost (initial price vs. inspection/swap downtime and replacement frequency). A higher-grade impregnated rope often pays back through longer service life and lower maintenance.

- Keep spare lengths of the same lot/heat when possible — variation between lots can affect spooling and behavior.

- Use NDT periodically offshore to catch internal damage before catastrophic failure.