Introduction

Wire rope lifting slings are critical tools in modern industry, designed to facilitate the safe lifting, hoisting, and transportation of heavy loads. They are fabricated from high-tensile steel wires twisted into strands, then laid into rope constructions, and finally assembled into slings with end fittings or splicing.

From towering construction sites to offshore platforms, and from shipyards to mining fields, wire rope slings play a vital role in material handling. Their strength, resilience, and adaptability have made them indispensable in environments where safety and efficiency are non-negotiable.

This comprehensive guide explores the fundamentals, constructions, applications, safety guidelines, advantages, and maintenance of wire rope lifting slings in detail.

1. Fundamentals of Wire Rope Slings

1.1 What is a Wire Rope Sling?

A wire rope sling is a specialized assembly created by attaching fittings, loops, or terminations to a length of wire rope, allowing it to connect to a crane hook and a load. It serves as a flexible yet robust link between the lifting equipment and the object being lifted.

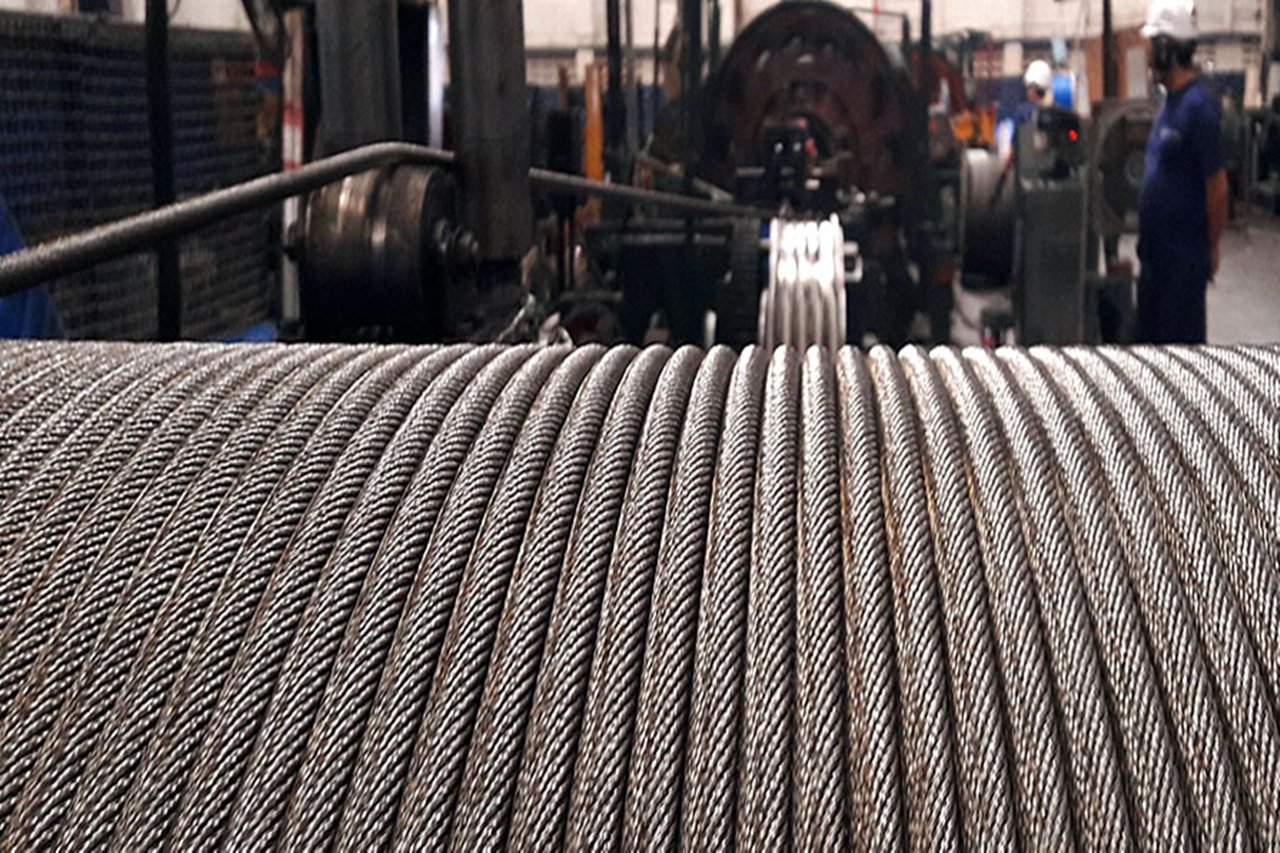

1.2 Structure of Wire Rope

Wire rope itself is composed of three essential parts:

- Wires: Small diameter steel filaments twisted together.

- Strands: Groups of wires twisted around a center wire.

- Core: The central element (fiber core or steel core) that supports strands and maintains rope shape.

This multi-layered construction gives wire rope slings their hallmark combination of strength, flexibility, and fatigue resistance.

2. Types of Wire Rope Lifting Slings

Wire rope slings are available in different designs, each suitable for particular lifting tasks.

2.1 Single-Leg Slings

- Consist of one length of wire rope with an eye or fitting on each end.

- Ideal for straight, vertical lifting of balanced loads.

- Common in manufacturing and logistics where objects are lifted vertically.

2.2 Double-Leg Slings

- Two wire rope legs connected to a master link.

- Provides greater load stability than a single-leg sling.

- Used when two attachment points are available on the load.

2.3 Triple- and Quad-Leg Slings

- Three or four wire rope legs connected to a common master link.

- Suitable for large, unbalanced, or irregularly shaped loads.

- Widely used in shipbuilding, steel fabrication, and offshore construction.

2.4 Endless Slings (Grommets)

- Formed by splicing a rope into a continuous loop.

- Extremely durable and can be rotated to distribute wear evenly.

- Often chosen for repetitive lifting operations.

2.5 Braided and Multi-Part Slings

- Made from multiple wire ropes braided together.

- Offer high flexibility, shock absorption, and reduced rotation.

- Favored in offshore lifting and heavy industry.

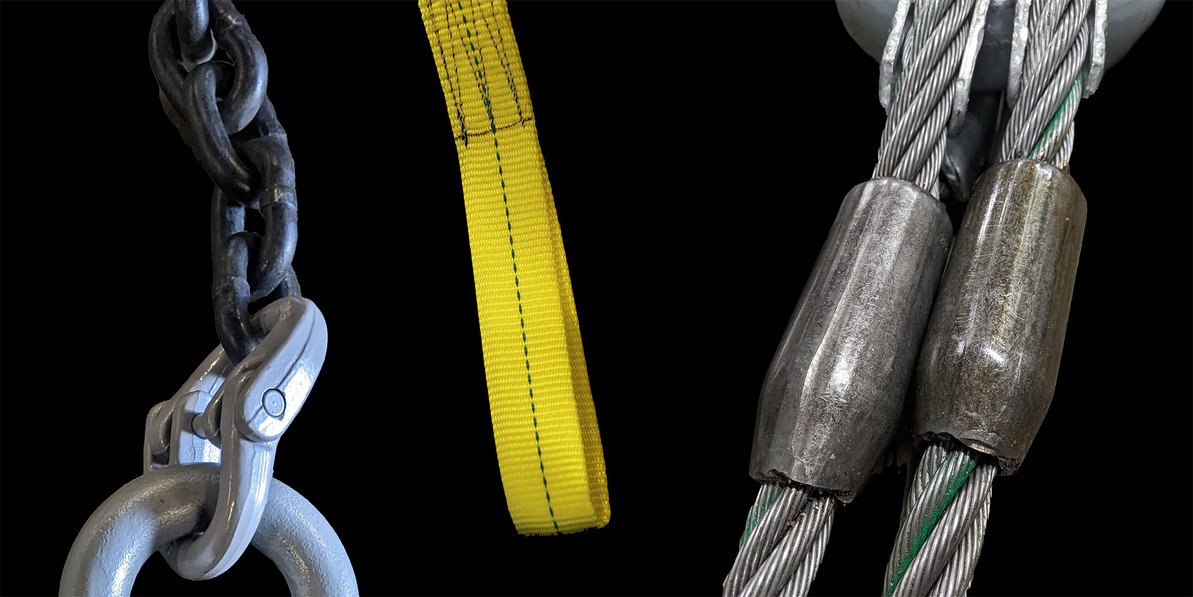

3. End Fittings and Terminations

The performance and usability of a wire rope sling depend heavily on its end fittings. Common types include:

- Thimbled Eyes: Wire rope loops reinforced with metal thimbles to reduce wear.

- Hooks: Eye hooks, grab hooks, and swivel hooks for direct load attachment.

- Shackles: Versatile connectors used to link slings with lifting points.

- Master Links & Rings: Central connectors for multi-leg slings.

- Sockets: Fixed terminations (spelter, swaged, or wedge type) for permanent fittings.

Each termination is chosen based on the load type, connection method, and working environment.

4. Advantages of Wire Rope Slings

Wire rope lifting slings offer multiple benefits over chains and synthetic slings:

- Strength-to-Weight Ratio: High lifting capacity without excessive bulk.

- Abrasion Resistance: Handles contact with sharp edges better than synthetics.

- Heat Resistance: Performs well in environments with high temperatures.

- Durability: Long service life with proper maintenance.

- Flexibility: Can wrap around loads and conform to irregular shapes.

- Cost-Effectiveness: Provides excellent value for heavy-duty lifting.

5. Applications of Wire Rope Slings

Wire rope slings are versatile and widely used in industries where heavy lifting is routine:

5.1 Construction Industry

- Hoisting steel beams, concrete blocks, and structural components.

- Moving prefabricated elements such as bridge segments or building panels.

5.2 Marine and Offshore

- Handling anchors, chains, and mooring equipment.

- Lifting subsea structures and offshore platforms.

5.3 Mining

- Transporting ore buckets, crushers, and excavation machinery.

- Hoisting equipment underground.

5.4 Manufacturing and Fabrication

- Positioning large machines, press molds, and heavy assemblies.

- Loading and unloading industrial parts.

5.5 Transport and Logistics

- Cargo handling at ports, warehouses, and freight terminals.

- Loading oversized machinery onto trucks or ships.

6. Safety in Using Wire Rope Slings

Safety is paramount when handling heavy loads. Improper use or failure to inspect slings can lead to accidents, injuries, and equipment damage.

6.1 Pre-Use Inspection

Operators should always check for:

- Broken wires or localized wire breaks.

- Kinks, birdcaging, or deformation.

- Corrosion or rust.

- Wear at end fittings.

- Core protrusion or rope crushing.

6.2 Discard Criteria

A sling should be retired if:

- The number of broken wires exceeds allowable limits (as per ISO/ASME standards).

- Severe corrosion or heat damage is visible.

- Diameter reduction indicates internal wear.

- The rope has been exposed to shock loads or chemical attack.

6.3 Safe Working Practices

- Never exceed the Working Load Limit (WLL).

- Use the correct sling type for the load and lift angle.

- Avoid sharp edges or pad them to prevent rope cutting.

- Do not drag slings along the ground.

- Always lift smoothly, avoiding sudden jerks.

7. Load Capacity and Angle Considerations

The capacity of a wire rope sling depends not only on rope diameter but also on the lifting configuration:

- Vertical Lift: Full rated capacity.

- Choker Hitch: Typically reduces capacity to 75–80% of rated load.

- Basket Hitch: Doubles capacity if load balance is maintained.

- Multi-Leg Slings: Load distribution varies with sling angle—smaller angles increase tension in legs.

Proper calculation of sling angle is essential to avoid overloading individual legs.

8. Maintenance and Storage

To extend the life of a wire rope sling:

- Lubrication: Apply suitable lubricants to minimize internal wear and corrosion.

- Cleaning: Remove dirt, grease, and contaminants after use.

- Storage: Keep slings in a dry, ventilated area away from chemicals.

- Rotation: Rotate slings in service to distribute wear evenly.

- Record Keeping: Maintain inspection logs and service history.

9. Industry Standards and Regulations

Wire rope slings are regulated by strict international standards to ensure performance and safety:

- ISO 7531 – Wire rope slings for general lifting service.

- EN 13414-1 – European standard for single-leg and multi-leg slings.

- ASME B30.9 – U.S. safety standard for slings.

- OSHA 1910.184 – Occupational safety regulations for lifting devices.

- CE Marking – Compliance with European safety directives.

Following these standards ensures slings are manufactured, tested, and certified for safe operation.

10. Comparison with Other Sling Types

| Feature | Wire Rope Slings | Chain Slings | Synthetic Slings |

|---|---|---|---|

| Strength | High | Very High | Moderate |

| Flexibility | Good | Limited | Excellent |

| Abrasion Resistance | High | Excellent | Poor |

| Heat Resistance | Moderate-High | Excellent | Low |

| Cost | Moderate | Higher | Lower |

| Lifespan (with care) | Long | Long | Shorter |

This table highlights why wire rope slings remain the go-to choice for many heavy industries—they balance performance, flexibility, and cost.

11. Future Trends in Wire Rope Slings

With industries evolving, wire rope sling technology is also advancing:

- Plastic-coated wire ropes to reduce corrosion and extend service life.

- High-performance steel grades offering greater strength-to-weight ratios.

- Smart inspection systems using RFID tags or embedded sensors.

- Customized sling designs tailored for specific offshore and subsea lifting operations.

These innovations continue to improve efficiency, reduce downtime, and enhance safety.

Conclusion

Wire rope lifting slings are indispensable in the world of heavy lifting. Their combination of strength, durability, and adaptability makes them the preferred choice across construction, offshore, mining, manufacturing, and logistics industries.

By understanding their types, applications, advantages, and safety requirements, businesses can select the right sling for each operation while ensuring compliance with international safety standards.

Regular inspection, proper maintenance, and correct usage are key to maximizing both safety and service life. As technology advances, wire rope slings will remain at the core of industrial lifting solutions, evolving to meet the ever-increasing demands of global industries.