Comprehensive Guide to Steel Wire Ropes in Construction and Decoration

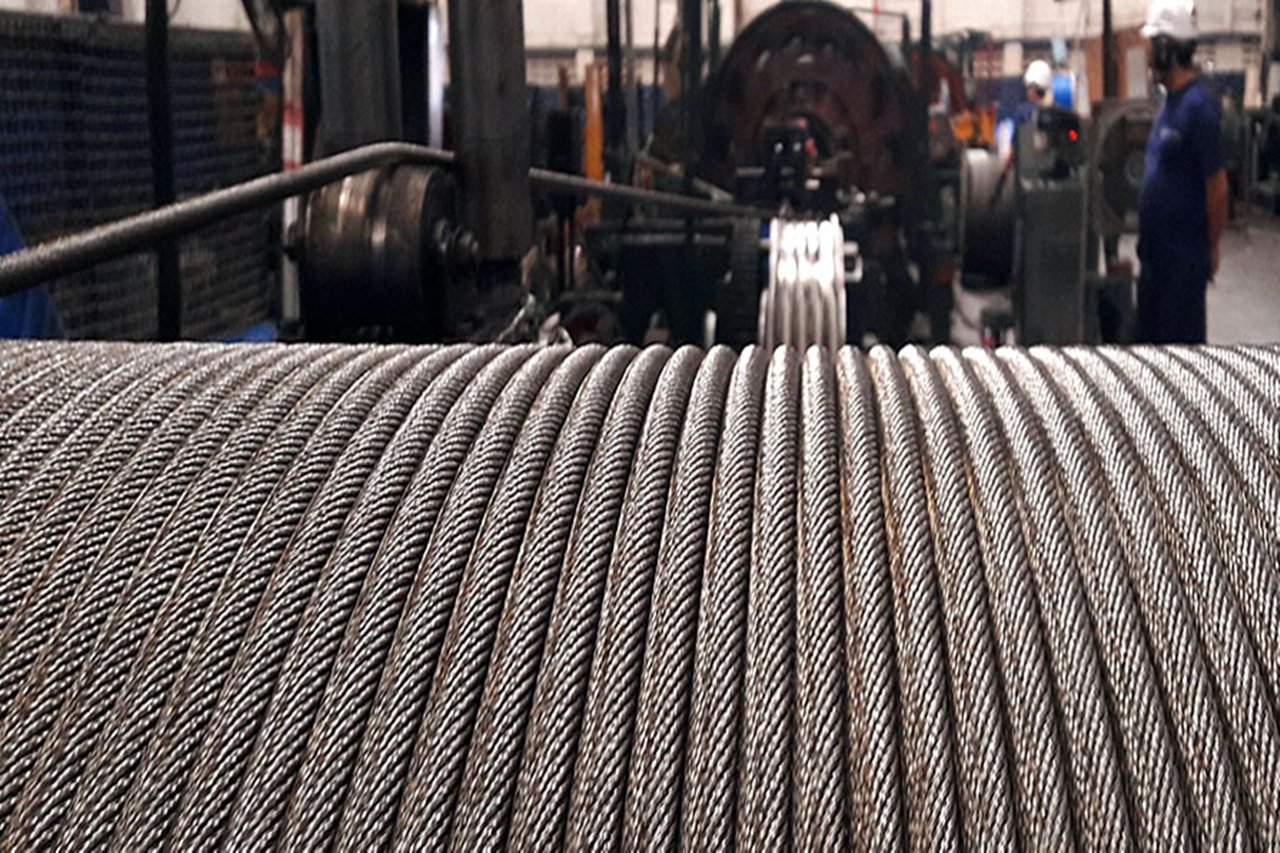

Steel wire ropes are fundamental components in various industrial, construction, and architectural applications. Renowned for their strength, durability, and versatility, these ropes are essential for lifting, rigging, securing, and tensioning operations. A thorough understanding of steel wire rope specifications, applications, and maintenance practices is critical for engineers, contractors, and designers who prioritize safety, efficiency, and longevity in their projects.

1. Understanding Steel Wire Ropes

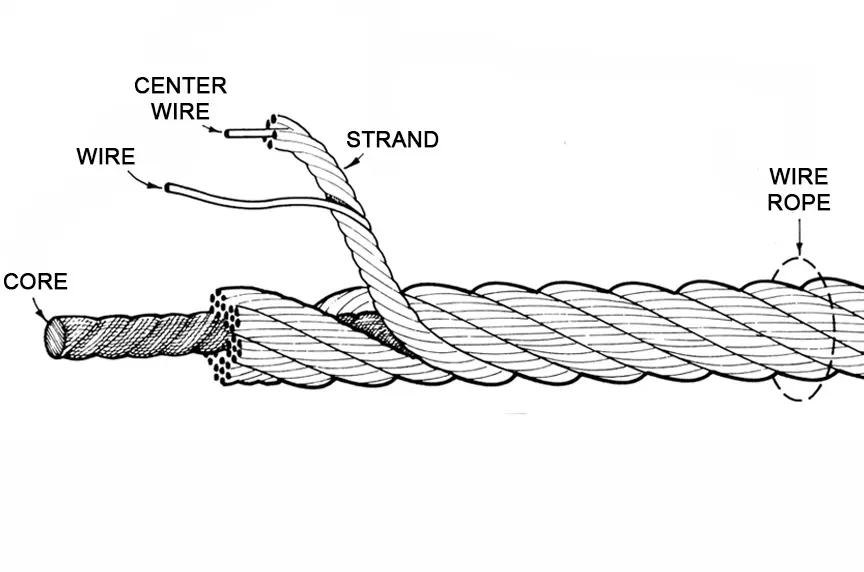

Steel wire ropes are composed of multiple strands of metallic wire twisted together around a central core, which enhances both strength and flexibility. The core can be either a fiber core (for more flexibility) or a steel core (for higher load-bearing capacity). The outer wires are arranged in layers, typically following standardized constructions such as:

- 7×19: Seven strands, each with 19 wires — highly flexible, ideal for pulleys or applications with frequent bending.

- 6×36: Six strands with 36 wires — more rigid and wear-resistant, commonly used for cranes and heavy lifting.

- 8xK26WS or 6xK36WS: Specialized constructions for hoist and luffing ropes, offering enhanced fatigue resistance.

Material considerations:

- Galvanized steel wire ropes: Coated with zinc for corrosion resistance, suitable for outdoor or marine environments.

- Bright (uncoated) steel ropes: Offer higher strength but require careful protection against moisture and chemicals.

Diameter and tolerance: The rope’s diameter must match the sheaves, drums, and load requirements. Standard tolerances are typically ±0.05–0.1 mm depending on the manufacturer, ensuring optimal fit and load distribution.

2. Applications in Construction

Steel wire ropes are indispensable in construction projects, serving both functional and structural purposes:

2.1 Lifting and Hoisting

- Cranes and hoists: Ropes are designed to lift heavy construction materials safely. Selection depends on load capacity, rope construction, and fatigue resistance.

- Elevators: High-strength, rotation-resistant ropes ensure safety and smooth operation in vertical lifting systems.

2.2 Structural Tensioning

- Cable-stayed bridges: Steel wire ropes act as primary tension elements, supporting decks and distributing loads efficiently.

- Suspension systems: Architectural projects often incorporate steel wire ropes for aesthetic cable support, tension rods, and overhead structures.

2.3 Safety and Temporary Support

- Scaffolding and hoarding: Ropes secure temporary structures or safety nets.

- Tie-backs for retaining walls: Tensioned steel wire ropes stabilize walls and structural elements during excavation.

3. Applications in Decoration and Architecture

Beyond heavy-duty industrial use, steel wire ropes are increasingly popular in interior and exterior design:

- Cable railings: Provide safety while maintaining minimal visual obstruction.

- Suspended installations: Wire ropes support lighting, signage, or art, allowing precise positioning and load management.

- Tensioned fabric structures: Ropes serve as structural anchors for tensile fabric roofs, canopies, or awnings.

In these applications, visual appeal is as critical as structural integrity, making galvanized or coated ropes with polished finishes common choices.

4. Selecting the Right Steel Wire Rope

Choosing the correct rope requires careful consideration of multiple factors:

- Load Capacity

- Evaluate the maximum expected load plus a safety factor, usually 5:1 for lifting applications.

- Consider dynamic loads, such as swinging or impact, which can exceed static weights.

- Environmental Conditions

- Moisture, chemicals, and temperature extremes can accelerate wear.

- Galvanized or stainless steel ropes are preferred in corrosive or outdoor environments.

- Flexibility Requirements

- Frequent bending or passage over sheaves requires flexible rope constructions (e.g., 7×19).

- Static or low-movement applications can use stiffer constructions (e.g., 6×36) for longer lifespan.

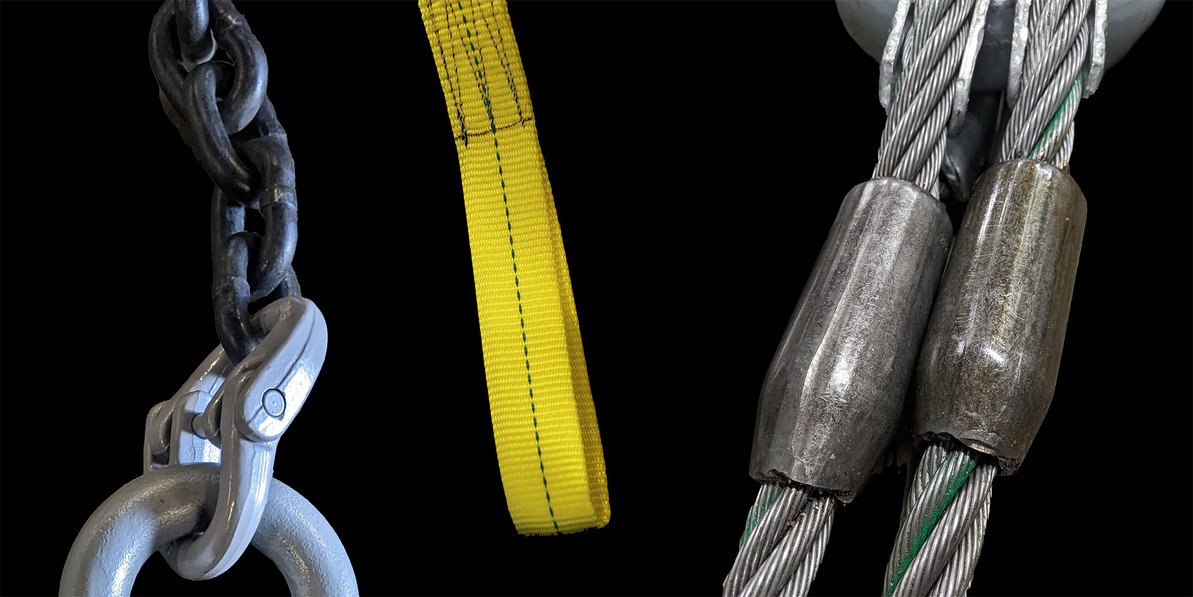

- End Connections

- Sockets, clips, swage fittings must match the rope type and load.

- Proper selection ensures secure load transfer and avoids premature failure.

5. Maintenance Practices for Longevity

Proper maintenance is critical to ensure safety and durability:

- Inspection

- Perform regular visual inspections for broken wires, fraying, corrosion, or diameter reduction.

- Pay attention to high-stress points: sheaves, drums, end fittings.

- Lubrication

- Apply rope lubricants to reduce friction between wires and strands, especially in hoisting and crane ropes.

- Use penetrating lubricants for internally lubricated ropes to protect the core.

- Storage

- Keep ropes dry, clean, and coiled to prevent kinks or corrosion.

- Avoid contact with sharp edges or chemicals.

- Replacement Guidelines

- Replace ropes when the number of broken wires exceeds standard limits (e.g., 6–12 broken wires in one lay length, depending on industry standards).

- Immediate replacement is required for core damage, severe corrosion, or diameter reduction exceeding 7–10%.

6. Enhancing Safety and Efficiency

Steel wire ropes are more than just lifting tools—they are critical safety components. Professionals can enhance performance and longevity by:

- Correct installation: Avoid sudden bends, crushing, or overloading.

- Use of compatible accessories: Ensure thimbles, sockets, and clamps match the rope’s diameter and construction.

- Monitoring and record-keeping: Track rope age, load cycles, and environmental exposure for predictive maintenance.

7. Conclusion

Steel wire ropes are versatile, high-performance solutions that combine strength, flexibility, and durability. From lifting heavy construction materials to creating elegant architectural features, these ropes are central to both industrial and decorative projects. Understanding their constructions, materials, applications, and maintenance practices allows professionals to select the right rope, optimize safety, and maximize operational efficiency. Whether for a high-rise crane, a bridge, or a stylish cable railing, the correct steel wire rope ensures reliability and longevity in any application.