Is wire rope a mystery to you? You see it everywhere, but what is it really? Many struggle to understand its true nature.

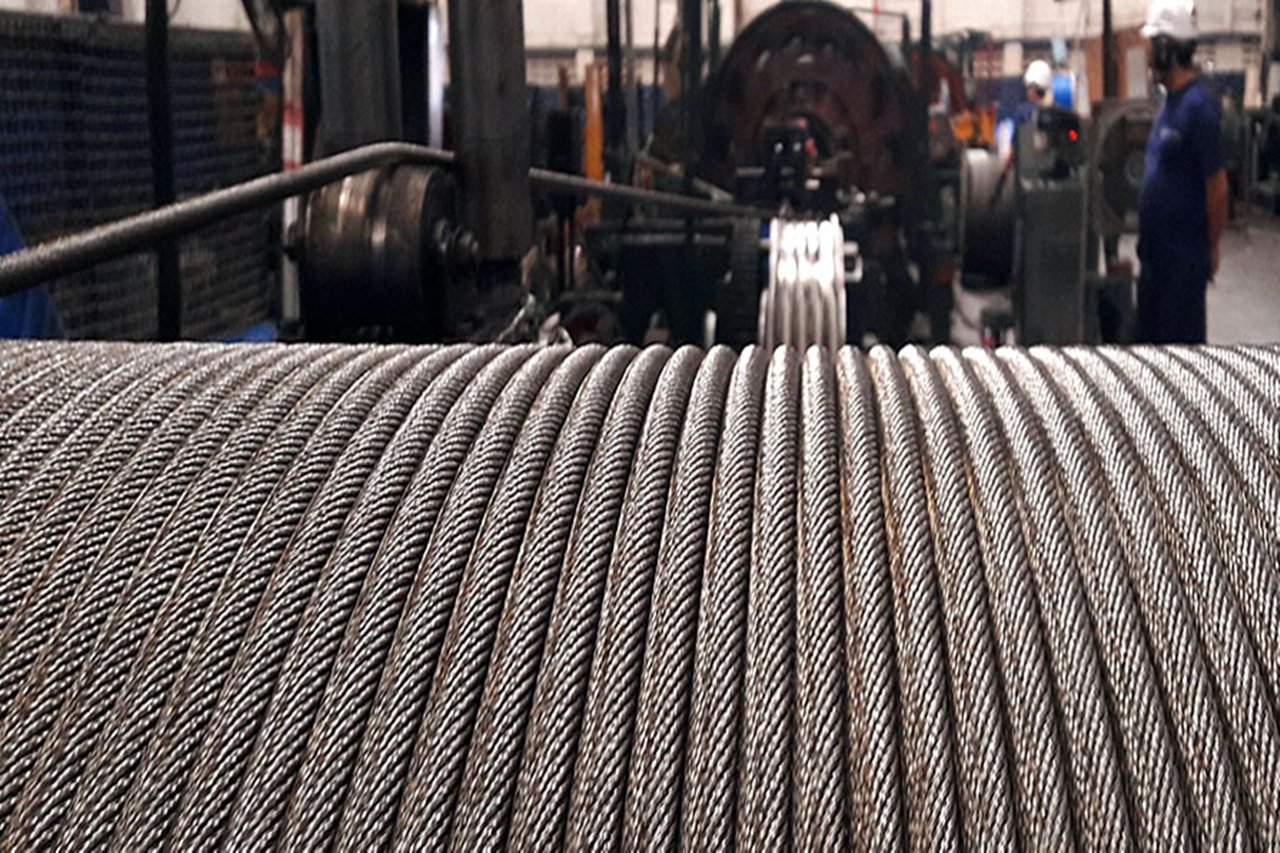

Wire rope is a complex strand of metal wires twisted together. It offers superior strength, flexibility, and durability compared to other materials.

Imagine a time when I also wondered about its hidden strength. It’s a story of discovery I’m eager to share.

What Makes Wire Rope So Strong?

Unraveling the strength of wire rope is fascinating. Let’s explore its construction.

Its strength comes from precisely engineered steel wires, forming strands, then twisted around a core. This structure maximizes tensile strength.

The Core’s Role in Wire Rope Strength

- Fiber Core (FC): Offers flexibility and cushioning.

- Independent Wire Rope Core (IWRC): Provides greater strength and crush resistance.

The Impact of Wire Diameter and Grade

The diameter and grade of the individual wires significantly influence the rope’s breaking strength. Higher tensile strength wires mean a stronger rope overall.

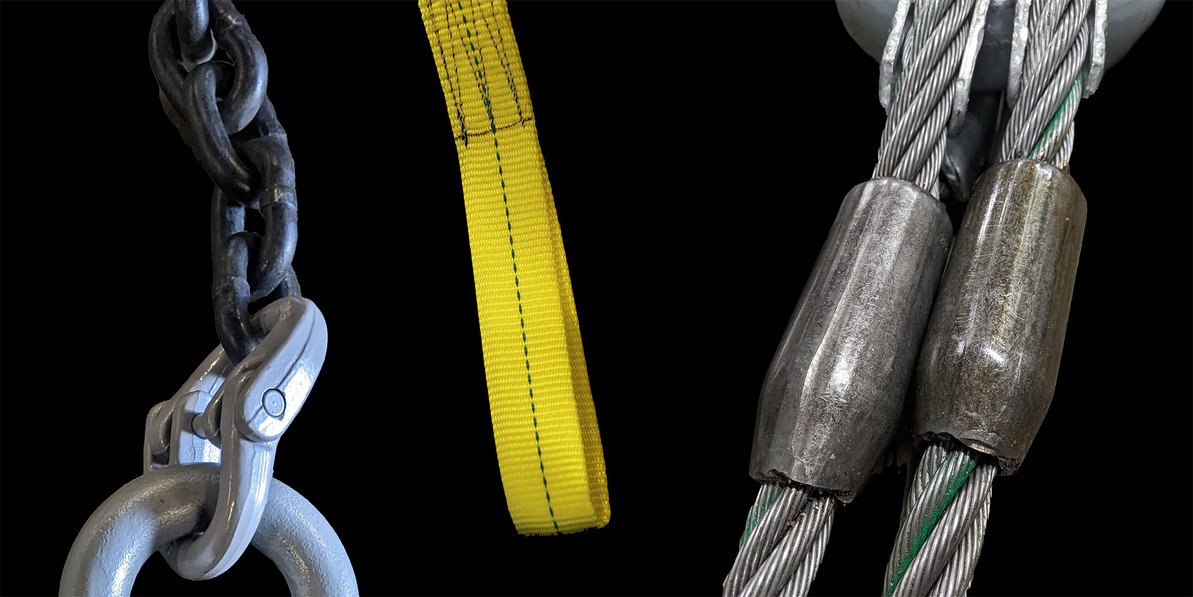

How Do Different Types of Wire Rope Serve Specific Needs?

Wire ropes aren’t one-size-fits-all. Each type has a purpose.

Different constructions and materials cater to diverse applications, from lifting heavy loads to specialized industrial uses.

Crane Wire Rope: Built for Heavy Lifting

Crane wire ropes need exceptional strength and flexibility. They must handle dynamic loads without failing.

Crane wire ropes are designed for high tensile strength and exceptional resistance to bending fatigue, crucial for safe and efficient lifting operations.

Elevator Wire Rope: Precision and Smoothness

Elevator ropes demand smooth operation and reliability. They ensure passenger safety.

Understanding Elevator Wire Rope Specifications

- Construction: Often 8×19 or 6×19 with a fiber core for flexibility.

- Lubrication: Crucial for reducing internal friction and wear.

- Galvanization: Provides corrosion resistance, extending lifespan.

The Importance of OEM Specifications

Adhering to Original Equipment Manufacturer (OEM) specifications is vital for elevator safety and performance.

Mining Wire Rope: Toughness in Demanding Environments

Mining operations expose wire ropes to extreme wear and tear. Durability is paramount.

- Abrasion Resistance: Mining ropes often feature specialized coatings or materials to withstand grit and rough surfaces.

- Corrosion Resistance: Exposure to moisture and chemicals in mines requires robust protection.

Synthetic Rope: A Lighter, Flexible Alternative

Synthetic ropes offer distinct advantages over steel wire ropes.

- Weight: Significantly lighter, making them easier to handle.

- Flexibility: Highly flexible, reducing kinking and improving knot-holding.

- Corrosion Resistance: Immune to rust and rot.

- Shock Absorption: Excellent at absorbing shock loads.

What Standards Ensure Wire Rope Quality and Safety?

Following industry standards is non-negotiable for quality.

Adherence to international standards like EN12385-4 guarantees that wire ropes meet rigorous safety and performance requirements.

EN12385-4: A Benchmark for Steel Wire Ropes

EN12385-4 sets clear guidelines for the construction, dimensions, and testing of steel wire ropes used in lifting applications.

Other Key Certifications: BV, CE, RMRS, DNV, ABS

Certifications from bodies like Bureau Veritas (BV), CE marking, Russian Maritime Register (RMRS), Det Norske Veritas (DNV), and American Bureau of Shipping (ABS) offer further assurance of product quality and compliance.

Can Wire Rope Be Customized to Specific Needs?

Customization is a key service for meeting unique project demands.

Yes, wire ropes can be customized with specific constructions, materials, and even logos to meet exact application requirements.

Custom Logo and Branding Options

Adding a custom logo can enhance brand visibility and product identification.

Plastic Impregnation for Enhanced Durability

Plastic impregnation offers superior protection against moisture and corrosion. It also improves internal lubrication and wear resistance.

Conclusion

Wire rope is a versatile, strong, and essential component across many industries.