Wire rope is an essential mechanical component used in a wide range of industries such as construction, mining, shipping, oil and gas, manufacturing, and transportation. Known for its exceptional strength, flexibility, and durability, wire rope is a type of rope that consists of multiple strands of steel wires twisted together around a central core. Its unique structure allows it to bear heavy loads, resist abrasion, and operate under demanding conditions where other materials, such as fiber ropes or chains, may not perform effectively.

The development of wire rope revolutionized lifting, hauling, and suspension applications in the 19th century. Since then, it has evolved into a highly engineered product with various designs, coatings, and constructions tailored to specific applications. Today, wire ropes are manufactured according to strict international standards to ensure safety, reliability, and performance.

A wire rope is not a single piece of metal, but rather an assembly of components carefully designed to function together. It is made up of three main parts: wires, strands, and the core.

Wires are the individual steel elements that form the building blocks of a rope. They can be made of high-carbon steel, stainless steel, or other alloys depending on the required strength and resistance to corrosion. Wires may have different surface finishes:

Bright (uncoated): plain surface, economical but prone to corrosion.

Galvanized: coated with zinc to improve corrosion resistance.

Plastic-coated: encased in a protective layer for extended durability.

The diameter of the wires affects the rope’s performance. Thicker wires provide better abrasion resistance, while thinner wires offer greater flexibility and fatigue resistance.

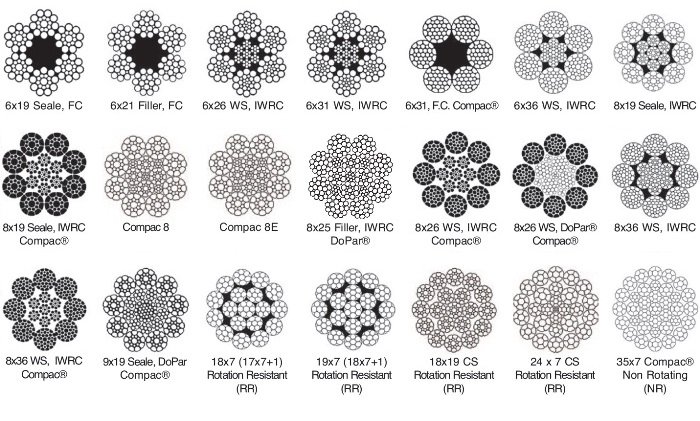

Strands are formed by twisting multiple wires around a central wire, known as the strand core. Each strand consists of several layers of wires, and the arrangement of wires in the strand determines the strand construction. Strands can be made in various designs, such as Seale, Warrington, Filler, or Warrington-Seale constructions, each offering unique combinations of strength, flexibility, and wear resistance.

The core provides support to the strands and maintains the rope’s shape during use. There are three main types of cores:

Fiber Core (FC): Made from natural or synthetic fibers, providing flexibility and lubrication retention.

Independent Wire Rope Core (IWRC): A small wire rope that acts as the central core, offering higher strength and resistance to crushing.

Wire Strand Core (WSC): A single wire strand used as the core, less common but still applied in specific designs.

The choice of core depends on the intended application. For heavy-duty and high-load environments, IWRC is preferred, while FC ropes are suitable where flexibility is more important.

Wire ropes are classified by their construction, usually represented by two numbers: the number of strands and the number of wires per strand. For example, a 6×19 rope has 6 strands with 19 wires in each strand.

6×7: Very robust, resistant to crushing, but less flexible.

6×19: General-purpose, offering a balance between strength and flexibility.

6×36: More wires per strand, excellent flexibility, but less resistant to abrasion.

8×19 and 8×36: Similar to 6-strand constructions but with more strands for added flexibility.

Rotation-resistant ropes (e.g., 18×7, 35×7): Designed with special strand arrangements to minimize rope rotation under load.

The lay refers to the direction in which the wires and strands are twisted.

Right Regular Lay (RRL): Strands laid right, wires laid left.

Left Regular Lay (LRL): Strands laid left, wires laid right.

Right Lang Lay (RLL): Both strands and wires laid in the same direction.

Left Lang Lay (LLL): Both strands and wires laid left.

Each lay type affects wear, resistance, and performance. For example, Lang Lay ropes provide better resistance to abrasion but are more prone to rotation.

The production of wire rope involves several precise steps to ensure strength, consistency, and safety.

Wire Drawing: High-carbon steel rods are drawn through dies to reduce their diameter and increase tensile strength.

Stranding: Wires are twisted together to form strands.

Closing: Strands are helically wound around a core to form the rope.

Lubrication: Lubricant is applied during manufacturing to reduce internal friction and protect against corrosion.

Finishing: Ropes may undergo surface treatments, galvanization, or plastic coating depending on application needs.

Advanced machinery and quality control systems are employed to ensure uniform diameter, accurate lay length, and compliance with international standards such as ISO, EN, DIN, and ASTM.

The performance of wire rope is defined by several critical properties:

Breaking Strength: Maximum load the rope can withstand before failure.

Working Load Limit (WLL): Safe load capacity, usually a fraction of breaking strength with a safety factor applied.

Flexibility: Ability to bend without fatigue.

Fatigue Resistance: Endurance against repeated bending over sheaves and drums.

Crushing Resistance: Resistance to deformation under heavy pressure.

Rotation Resistance: Ability to resist unwinding or spinning under load.

Corrosion Resistance: Protection against rust, often achieved through galvanization or stainless steel.

Wire ropes are used across diverse industries due to their strength and versatility.

Tower cranes, mobile cranes, and overhead cranes use wire ropes for hoisting, luffing, and load suspension.

Elevators and hoists rely on wire ropes for safety and smooth operation.

Suspension bridges utilize wire ropes as main cables, hangers, and support elements.

Wire ropes are critical for mine hoisting systems, draglines, and shovels.

They handle massive loads and operate in harsh, abrasive conditions.

Used in mooring lines, towing cables, and winches.

Offshore platforms rely on corrosion-resistant ropes for anchoring and lifting.

Drilling rigs employ wire ropes for draw works, crown blocks, and traveling blocks.

Specialized non-rotating ropes are used in deep drilling applications.

Used in conveyor systems, steel mills, and machinery.

Wire ropes provide stability and safety in theaters for stage rigging and in sports facilities for cable-supported structures.

Proper inspection and maintenance are essential to ensure safety and extend rope service life.

Wire ropes should be regularly inspected for:

Broken wires (localized or distributed).

Wear and abrasion.

Corrosion or rust.

Core protrusion or strand distortion.

Diameter reduction.

Birdcaging (outer strands opening).

International standards define discard criteria, such as maximum number of broken wires within a rope lay length.

Apply lubricants regularly to reduce internal friction.

Store ropes properly in dry, ventilated areas.

Avoid shock loading and kinking.

Use correctly sized sheaves and drums to minimize fatigue.

Wire ropes offer unique advantages over other lifting mediums:

High tensile strength.

Ability to absorb shock loads.

Flexibility for bending over sheaves.

Long service life under proper use.

Wide variety of constructions to suit different applications.

Despite its advantages, wire rope has limitations:

Susceptible to corrosion if unprotected.

Requires regular inspection and lubrication.

Heavier than synthetic ropes, increasing handling difficulty.

Limited fatigue life in extreme bending conditions.

Modern industries demand wire ropes with higher performance, safety, and environmental resistance. Current trends include:

Plastic-impregnated ropes: Providing longer life through internal protection.

High-performance steel alloys: Enhancing strength-to-weight ratio.

Non-rotating ropes: Improving safety in deep hoisting applications.

Smart monitoring systems: Sensors and IoT-based inspection tools to detect wire breakage, tension, and fatigue.

Sustainability is also driving innovations in coatings, recyclability, and manufacturing efficiency.

Wire rope is a cornerstone of modern industry, enabling safe lifting, hauling, and structural support across countless sectors. Its engineered construction, strength, and adaptability make it indispensable in demanding environments. Understanding its structure, types, properties, and maintenance practices is essential for professionals to ensure safe and efficient operations.

With continuous advancements in material science, manufacturing technology, and monitoring systems, the future of wire rope promises even greater reliability, performance, and safety.

We Produce a wide range of wire rope models and provide full customization to meet your specific needs. Customers can choose the diameter, length, lay direction, and strength grade, as well as additional treatments such as galvanization or plastic coating. Our wire ropes are designed for reliability, durability, and high performance across various industrial applications.

We provide high-quality wire ropes tailored to your needs, ensuring strength, safety, and long-lasting performance for every application.

WhatsApp us

Free samples, product catalog, and expert consultation available.