Wire rope slings are indispensable lifting devices widely used in construction, manufacturing, mining, offshore, shipping, and many other industries. They are fabricated from steel wire ropes and designed for lifting, rigging, pulling, and load-securing operations. The main function of a sling is to connect a load to lifting equipment such as a crane, hoist, or winch, allowing safe and efficient handling of heavy or awkwardly shaped objects.

Unlike synthetic slings or chain slings, wire rope slings offer a unique combination of high strength, durability, abrasion resistance, and cost-effectiveness. They can withstand tough working environments, resist cutting and crushing forces, and are relatively easy to fabricate in different configurations. Because of these advantages, they remain one of the most common choices for heavy-duty lifting tasks worldwide.

To fully understand wire rope slings, it is essential to first understand the construction of wire rope itself.

A typical wire rope is composed of three main parts:

Wires – Small steel filaments, drawn to precise diameters and strengths. The wires form the fundamental load-bearing elements.

Strands – A number of wires twisted together form a strand. Strands provide both strength and flexibility.

Core – The central support around which strands are laid. The core may be:

Fiber core (FC): Made from natural or synthetic fibers, offering flexibility and lubrication retention.

Independent wire rope core (IWRC): A separate steel wire rope core that increases strength, crush resistance, and temperature tolerance.

Wire ropes are categorized by the number of strands and the number of wires per strand. Typical constructions include:

6×19 (6 strands, 19 wires each): Balance of strength and flexibility.

6×36: Higher flexibility, used for slings requiring more bend capacity.

8×19 or 8×36: Even greater flexibility, commonly used in rotation-resistant or special slings.

The choice of construction affects the sling’s performance, fatigue resistance, and service life.

Wire rope slings are fabricated in different configurations to meet diverse lifting requirements. The most common types include:

A single-leg sling consists of a single length of wire rope with an end fitting on each side, such as hooks, rings, or thimbles. It is used for vertical lifts and straightforward applications.

Two-leg slings: Provide better load stability.

Three-leg and four-leg slings: Used for lifting large or irregularly shaped loads, distributing weight evenly among legs.

An endless sling is a continuous loop of wire rope. It can be used in a choker, basket, or vertical hitch and offers flexibility in handling loads from different angles.

Braided slings: Multiple wire ropes braided together for enhanced flexibility and load distribution.

Grommet slings: Made by forming a continuous loop without mechanical fittings, offering high strength-to-diameter ratio.

Cable-laid slings: Constructed from several wire ropes laid together, providing extreme flexibility.

Rotation-resistant slings: Designed for lifting long loads that must remain stable without rotation.

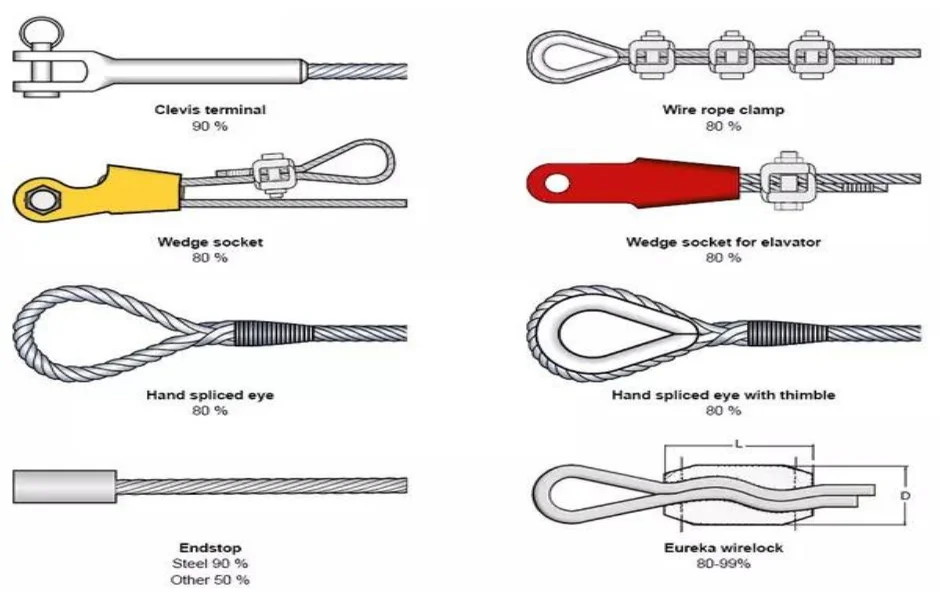

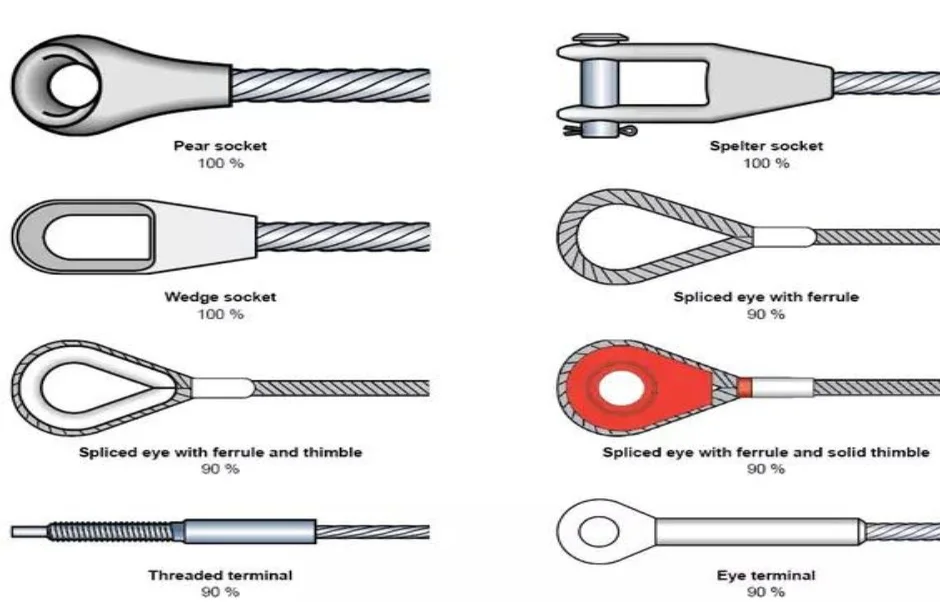

Wire rope slings are manufactured through several processes to ensure secure end terminations and reliable performance.

A mechanical sleeve, often aluminum or steel, is compressed around the rope ends to form an eye. This is the most common and cost-effective fabrication method.

Skilled workers manually interweave rope strands to form a splice. Though labor-intensive, it offers flexibility for custom slings.

A popular type of mechanical splice where strands are unlaid, re-laid in opposite directions, and secured with a metal sleeve. It combines strength with security.

Wire rope ends are fitted into conical sockets filled with molten zinc, resin, or other compounds. This provides a nearly 100% efficient termination, often used in heavy-duty and permanent applications.

The performance of a wire rope sling is greatly influenced by the end fittings, which connect the sling to the load or lifting equipment. Common fittings include:

Thimbles – Protect the rope eye from abrasion and crushing.

Hooks – Various designs (clevis, eye, swivel, latch) for easy attachment.

Shackles – U-shaped fittings with a pin for secure connections.

Master Links – Large rings used for multi-leg slings.

Swivels – Allow rotation under load, preventing rope twisting.

The same wire rope sling can be used in different hitches, depending on the lifting requirement:

One sling leg connects the load directly to the lifting hook. Suitable for straight lifting but does not prevent load rotation.

The sling wraps around the load and passes through one eye or fitting. It provides better load control but reduces lifting capacity due to bending stress.

The sling forms a “U” shape under the load, with both ends attached to the lifting hook. It doubles capacity compared to a vertical hitch but requires load balance.

Multi-leg slings attach to multiple points on the load, offering excellent load stability. Common in lifting large steel structures or machinery.

High strength-to-weight ratio – Can lift very heavy loads without excessive weight.

Durability – Resistant to abrasion, crushing, and high temperatures.

Versatility – Available in multiple configurations for different lifting methods.

Cost-effectiveness – Long service life and relatively low maintenance compared to chains.

Flexibility – Can wrap around loads without damage (when properly applied).

While wire rope slings are robust, they also have limitations:

Susceptible to corrosion if not properly lubricated or galvanized.

Can suffer from kinking or crushing when improperly handled.

Lower resistance to shock loading compared to chains.

Require regular inspection and maintenance to ensure safety.

Proper inspection and care are critical to extend service life and prevent accidents.

Daily/Pre-use inspections: By the operator before each lift.

Frequent inspections: Performed weekly or monthly, depending on use.

Periodic inspections: Conducted by a qualified person every 3–12 months.

Wire rope slings should be removed from service if any of the following are observed:

Excessive broken wires (number varies by standard, e.g., OSHA, ISO, ASME).

Severe abrasion, kinking, birdcaging, or crushing.

Corrosion reducing rope diameter.

Damaged end fittings or cracked sleeves.

Loss of more than 10% of rope diameter.

Apply lubrication regularly to reduce friction and prevent corrosion.

Store slings in dry, ventilated areas.

Avoid dragging slings on the ground or over sharp edges.

Use protective sleeves where loads have sharp corners.

Wire rope slings are governed by multiple international standards, ensuring safe usage:

ASME B30.9 (USA) – Standards for slings.

OSHA 1910.184 – Safety requirements for sling use in general industry.

ISO 7531 – Specifications for wire rope slings.

EN 13414 (Europe) – Safety standards for steel wire rope slings.

Compliance with these standards ensures uniform safety practices and helps prevent accidents.

Wire rope slings are found in almost every heavy-duty industry:

Construction – Lifting steel beams, precast concrete, scaffolding.

Offshore and Marine – Mooring, towing, anchor handling, heavy lift vessels.

Mining – Hoisting equipment, draglines, and conveyors.

Manufacturing – Handling machinery, coils, and heavy components.

Shipbuilding – Rigging massive ship sections.

Transport and Logistics – Loading and unloading heavy cargo.

With advances in metallurgy, coatings, and rope manufacturing, wire rope slings are becoming more efficient and durable. Key trends include:

Plastic-coated wire ropes for corrosion protection.

Rotation-resistant ropes with higher load stability.

Smart slings equipped with RFID chips for traceability and inspection records.

Hybrid slings combining wire rope with synthetic fibers for specific applications.

Wire rope slings remain an essential tool in lifting and rigging operations worldwide. Their combination of strength, durability, and adaptability makes them the preferred choice for heavy-duty applications. However, safe and efficient use requires proper selection, inspection, and maintenance according to international standards.

From single-leg to multi-leg, endless to grommet, wire rope slings offer solutions for nearly every lifting challenge. As industries evolve, innovations in design and materials will continue to enhance performance, safety, and service life.

We provide high-quality wire ropes tailored to your needs, ensuring strength, safety, and long-lasting performance for every application.

WhatsApp us

Free samples, product catalog, and expert consultation available.